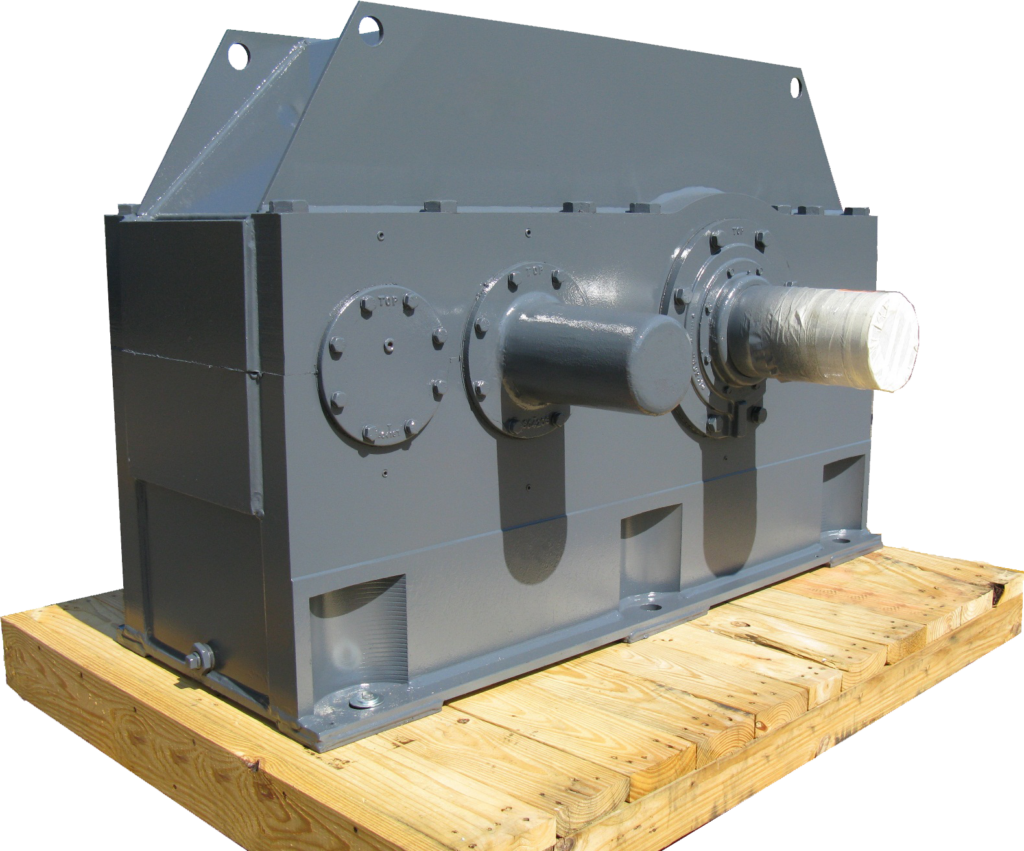

Gearboxes

C-B Gear & Machine stands as a comprehensive gearbox repair facility specializing in providing enhancement solutions for a wide array of gearbox types and manufacturers. Our commitment revolves around identifying cost-effective, high-quality repair options for your gearbox, aiming to elevate productivity and minimize downtime. Renowned as one of the largest repair facilities in North America, we offer expedited services for emergencies.

Our meticulous process commences with a thorough disassembly and inspection of each component, encompassing the gearbox housing. Subsequently, after conducting in-depth analysis of the application, installation, and operational conditions, we furnish clients with a detailed inspection report and a comprehensive quotation.

Being equipped to manufacture various gear types and sizes internally, we eliminate dependency on OEM components. This assurance provides our customers with the confidence that quality control remains under our direct oversight.

REPAIR PROCEDURES

Initial Inspection: This involves a comprehensive assessment of the gearbox to identify visible damage, wear, or any apparent issues.

Disassembly: Careful dismantling of the gearbox to access internal components for a more thorough inspection. This involves removing covers, gears, shafts, bearings, seals, and other parts.

Cleaning and Assessment: Parts are cleaned and examined for wear, damage, or irregularities. This step involves magnetic particle inspection, dye penetrant testing, or other methods to identify potential issues.

Component Replacement or Repair: Damaged or worn-out components such as gears, bearings, seals, and shafts may need replacement or repair.

Reassembly: Putting the gearbox back together with the replaced or repaired components, notating tolerances.

Testing: Performing tests to ensure the repaired gearbox operates as expected. Spin Testing: check for leaks, noise, vibration, heat, and proper functionality under varying conditions.

Quality Assurance: A final inspection and quality check to ensure all repairs and adjustments meet the required standards.

Documentation and Reporting: Detailed documentation of the repair process, including findings, actions taken, and any recommendations for future maintenance provided to customer.

PREMATURE FAILURES

Should your gearbox exhibit premature signs of failure, we encourage you to notify us, enabling collaborative efforts to extend its operational lifespan. Our approach involves a meticulous examination of the unit, considering factors such as pitting, overload, misalignment, fatigue, and soft foot, utilizing the information provided by you to address these concerns and enhance the gearbox’s longevity.